Here’s David’s entry for Power BI Challenge 18. @davidcenna, feel free to add other details of your work.

Here’s how David described it:

This current challenge introduced me to OEE. It was really fun trying to find my way out to get meaningful insight and then picking the suitable model, visual and theme for the challenge. However, here I am.

You can click here to view my Power BI report. I am so sorry that it is coming late this time around.

or use this URL directly to view https://app.powerbi.com/groups/cbbceb51-b4d4-42e4-a555-b0042e04abe3/reports/ec200f59-d0e3-4974-a222-0ab85ecfc27c/ReportSectionc61443ac188526d463c0

The OEE Calculation

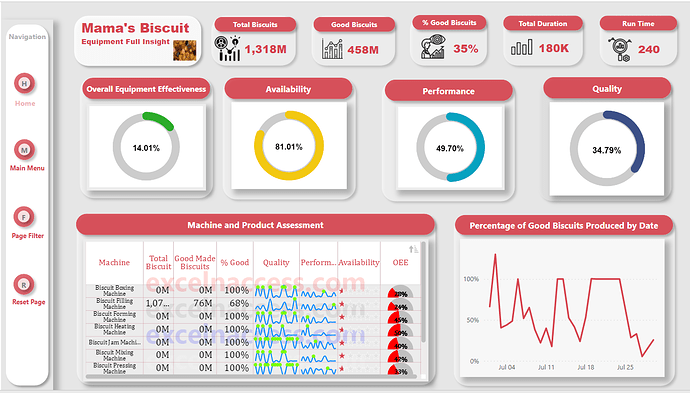

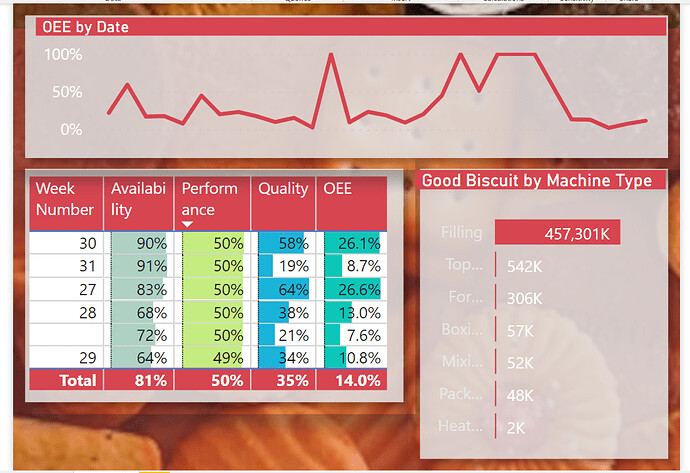

The preferred OEE calculation is based on the three OEE Factors: Availability, Performance, and Quality.OEE Formula

OEE takes into account all losses, resulting in a measure of truly productive manufacturing time. It is calculated as:OEE = [Performance] * [Quality] * [Availability]

Availability

Availability takes into account all events that stop planned production long enough where it makes sense to track a reason for being down (typically several minutes).Availability is calculated as the ratio of Run Time to Planned Production Time:

Availability = DIVIDE([No Order],[Total Duration],0)

Run Time is simply Planned Production Time less Stop Time, where Stop Time is defined as all time where the manufacturing process was intended to be running but was not due to Unplanned Stops (e.g., Breakdowns) or Planned Stops (e.g., Changeovers).

Run Time = CALCULATE([Total Duration], FILTER(‘Fact’,‘Fact’[OEE Category] = “Run Time”))

Performance

Performance takes into account anything that causes the manufacturing process to run at less than the maximum possible speed when it is running (including both Slow Cycles and Small Stops).Performance is calculated as:

Performance = DIVIDE([No Order Total], [Total Biscuit], 0 )

Quality

Quality takes into account manufactured parts that do not meet quality standards, including parts that need rework. Remember, OEE Quality is similar to First Pass Yield, in that it defines Good Parts as parts that successfully pass through the manufacturing process the first time without needing any rework.Quality is calculated as:

Quality = DIVIDE([Good Biscuit],[Total Biscuit],0)

Here’s the link to the report:

To learn about the real-life scenario presented for the challenge, be sure to click on the image below.