Here’s Hideo’s entry for Power BI Challenge 10. @Hideo, feel free to add other details of your work.

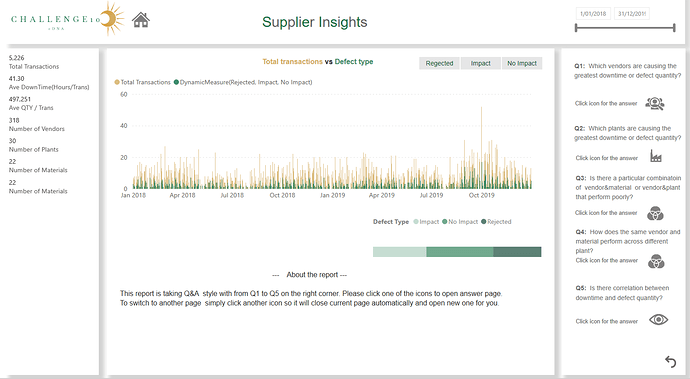

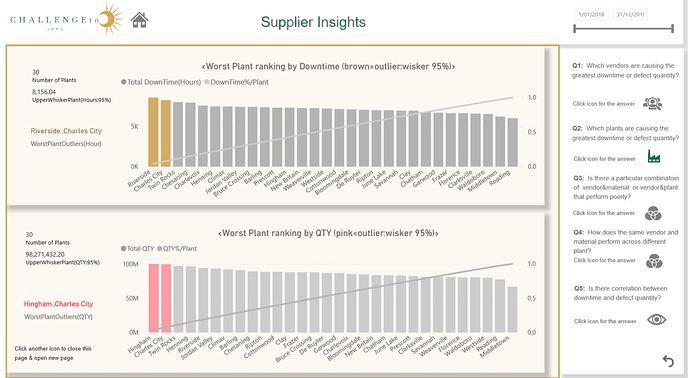

(First Screen)

I have tried to as simple as possible for the first screen so the consumer can have enough time prepare for the next screen.

This time I took Q&A style. Please press icons to answer for the questions.

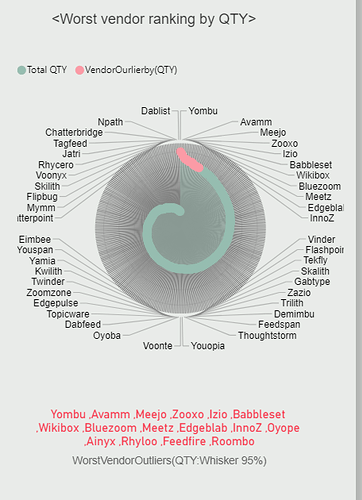

(Q1 screen)

For the first question. Rader chart is showing from the worst ranking. Worst start from top and goes around down as clockwise like a snail shell. Outliers stands out as gold or pink colour.

To go to next screen, simply press another icon which will close current screen and automatically open the desired one and I think it is easier for the consumer.

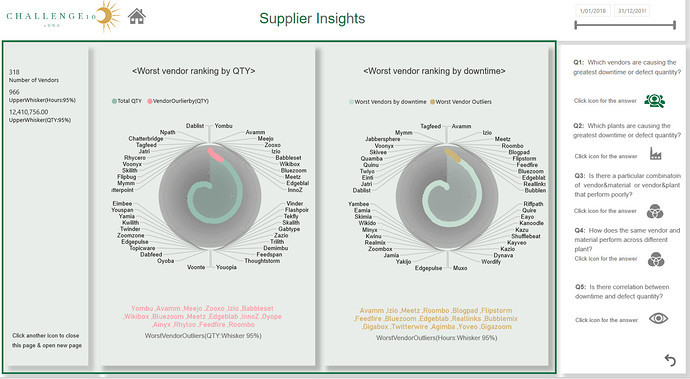

(Q2 screen)

Similar question as Q1 but I have used different visual to make sure consumer won’t get bored.

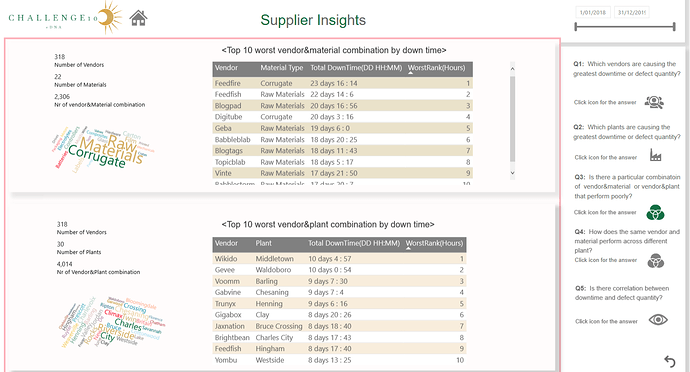

(Q3 screen)

Worst vendor and material combinations.

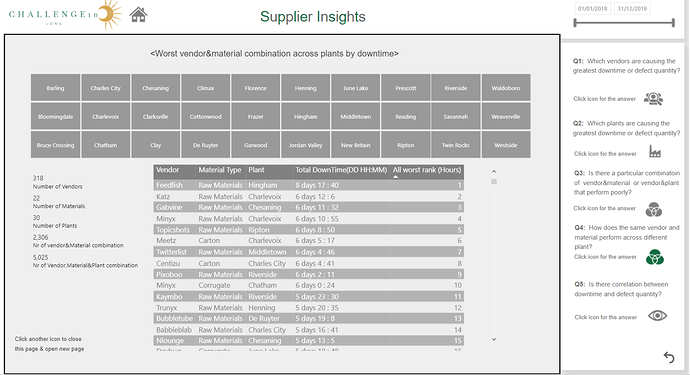

(Q4 screen)

Another worst combination including plant.

(Q5 screen)

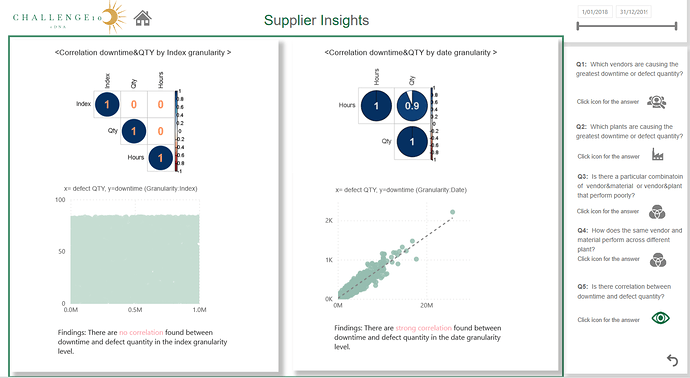

If there is correlation between downtime and defects QTY , I wanted to create overall worst ranking for all the combinations but as the data showing there is no correlation in the index

(I have created index) level so I decided not to create overall ranking.

Here’s the link to the report:

To learn about the real-life scenario presented for the challenge, be sure to click on the image below.