Hi everyone, this is an entry submitted by Afolashade Allinson sent to us via email.

Here’s how Afolashade Allinson described it:

PATTERNS AND FINDINGS FROM THE DATA SET PROVIDED

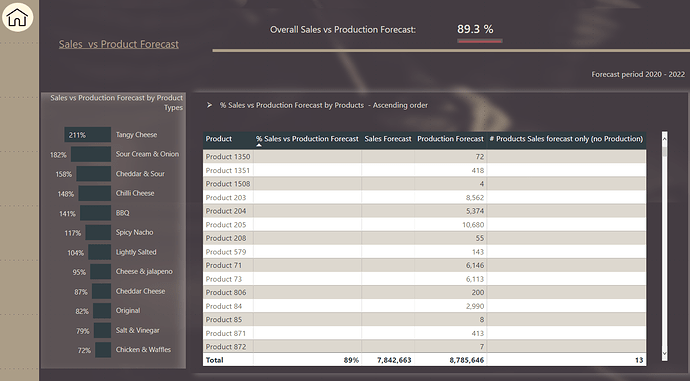

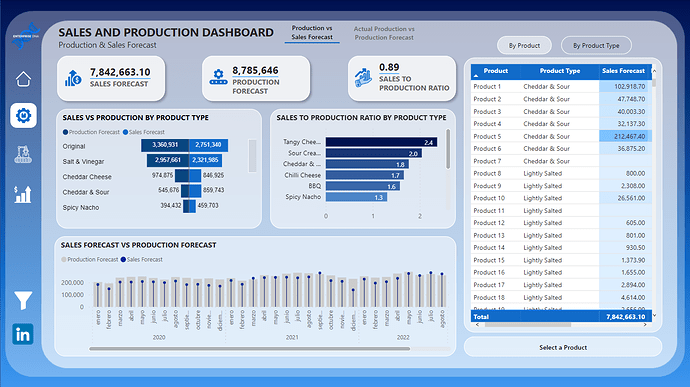

Both sales and production forecasts are of great importance in running any business. Having a crystal-clear vision of what to anticipate in the future will help the organization with planning ahead and ensuring sufficient production to equate with the demands of the market. Looking through the data provided the following were observed:

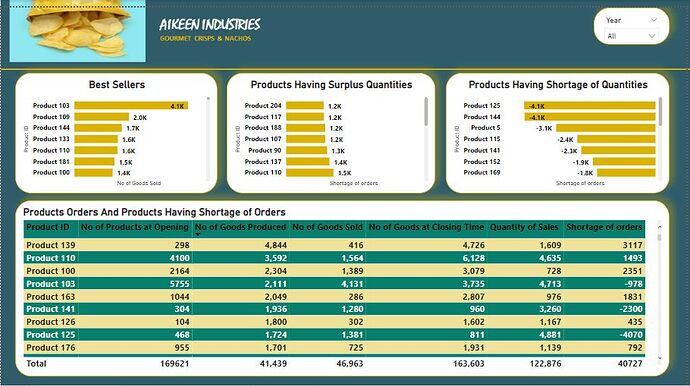

Best Sellers Products

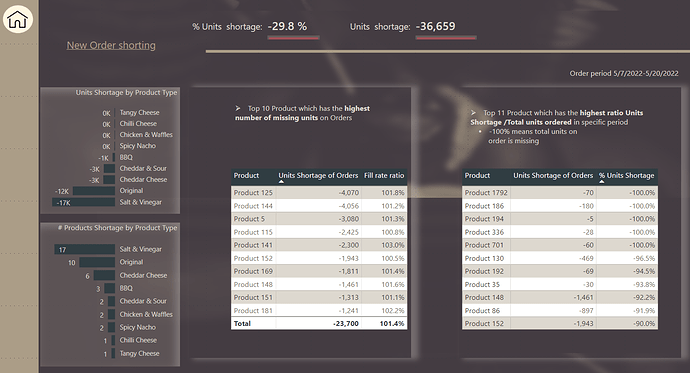

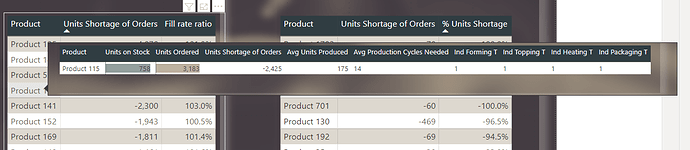

Best seller products for example, Product 103 is at shortage as of the last day of inventory. Product 103 as of May 24, 2022, was 978 units short based on sales order made. Generally, Shortage of order is at 33.14 percent and should be reduced to zero. Fill- out rate of products is at 0.78 which means if not increased there will be continuous shortage of products of items that are in strong demand.

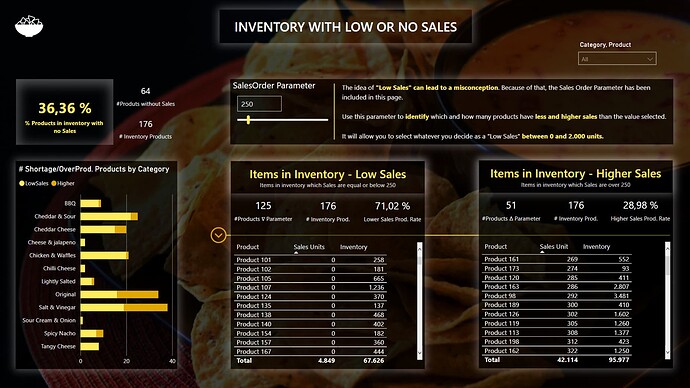

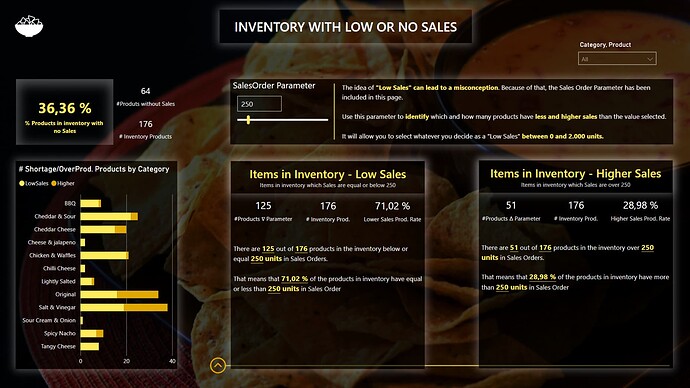

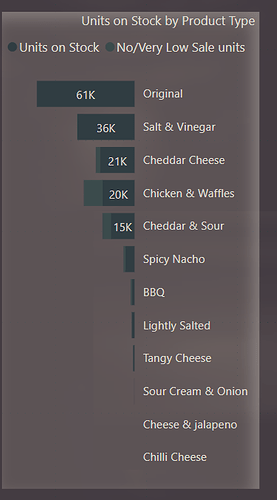

Excess quantities

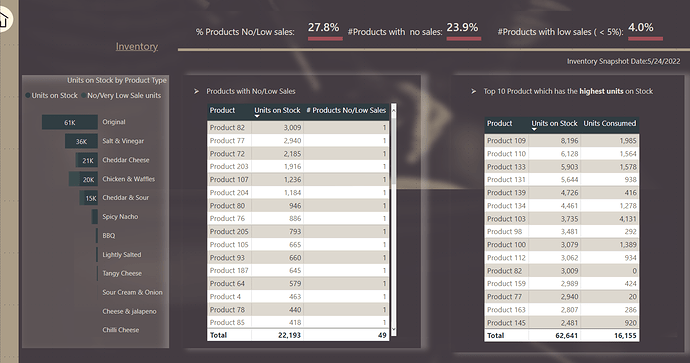

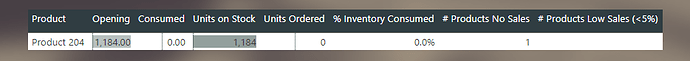

Some products have excess quantities meaning a large number are available in stock but demand for them is low hence will incur cost of storage. Having high production of less demanded products means the company must stock excess production in inventory, detaining payment and increasing cost of storage.

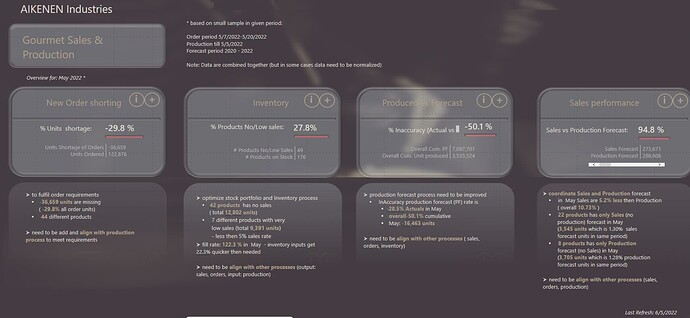

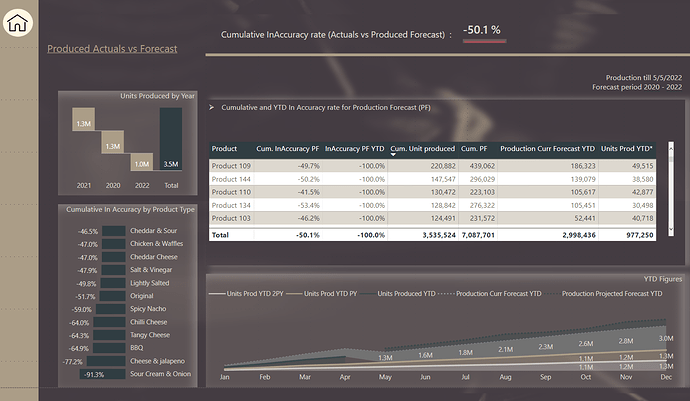

Accuracy of Production Forecast

Forecasting Manufacturing and production is a method of predicting the quantity of products that will be produced in each timeframe to match the sales forecast.

It is important that production levels match up to the actual market demands for a business to be successful. Having truncated production will lead to a company not meeting customers demands which implies unhappy customers and ultimately loss of sales.

Accuracy of forecast based on data is at 40.97 percent and needs to be increased urgently by finding more efficient ways to forecast production.

RECOMMENDATIONS AND CONCLUSIONS

SALES TEAM

Sales team needs to understand that sales forecast is prognostic of the number of products that will be sold in the time ahead. These predictions should be made based on sales trend at different periods in time. For example, January of every year have seen increase in demands and sales team should be prepared for such increase.

Methodical forecasting needs to be Implemented. An inventory management software should be considered for forecasting. Foreseeing and contemplating an increase in orders is essential for a practicable turnaround time on products. Guessing game must be totally eliminated from selling and manufacturing prediction techniques.

Predictive Forecasting must be enforced with the use of AI and machine learning to scrutinize past data to efficiently predict future sales.

PRODUCTION TEAM

Forecasting production is giving an estimate of the demand a company is expecting to see in the future. Production forecasting also helps businesses in predicting the number of resources that will be needed in manufacturing the forecasted products demand.

Production team should make predictions based on steady trends in company data. If the level of production levels grows by 1 percent each month for the past three years, then we can predict same for the next month.

It is also critical that production team starts looking at Inventory before making production forecast. We do not want to surpass demand for a product neither do we want to run out of required resources needed for production. Production managers should keep abreast of stock and inventory while making predictions.

A base volume of inventory is obligatory to fulfil short-term demand disparity, but if there is a towering inventory on a particular product, the production of such product must be lowered until stock has reduced to the suitable level.

PITFALLS OR SHORTCOMINGS OF YOUR ANALYSIS.

Major pitfall of the analysis will be an incomprehensive and very little number of sales historical data.

You may view the full report here: Afolashade Allinson

Please feel free to give Afolashade Allinson your feedback on her report.

Thanks!