Hi @myassay75,

One observation, you have a massive Date table, if at all possible restrict that to the number of years you actually require. Because some calcs are now iterating over a very large Date table.

You could for example set up a dynamic start- and enddate for your date table, here’s more on that.

Next I created a couple of measures:

This calculates the last ProductPlanning[Date ] with an inventory value.

LastStockDate =

CALCULATE( LASTDATE( ProductPlanning[Date ] ),

FILTER( ALL( ProductPlanning ),

ProductPlanning[Current inventoery ] <>0 &&

NOT( ISBLANK( ProductPlanning[Current inventoery ] )) &&

ProductPlanning[Date ] <= MAX( viewDates[Date] )

))

This returns that Inventory value

Inventory =

CALCULATE( SUM( ProductPlanning[Current inventoery ] ),

FILTER( ALL( viewDates ), viewDates[Date] = [LastStockDate]

))

Used a cumulative pattern for Demand

Cum Demand =

VAR InventoryDate = [LastStockDate]

VAR ThisDate = MAX( viewDates[Date] )

RETURN

CALCULATE( SUM( ProductPlanning[Demand ] ),

DATESBETWEEN( viewDates[Date], InventoryDate, ThisDate )

)

And for Replenishment

Cum Replenishment =

VAR InventoryDate = [LastStockDate]

VAR ThisDate = MAX( viewDates[Date] )

RETURN

CALCULATE( SUM( ProductPlanning[On Order ] ),

DATESBETWEEN( viewDates[Date], InventoryDate, ThisDate )

)

Finally

Current Inventory level =

[Inventory] - [Cum Demand] + [Cum Replenishment]

.

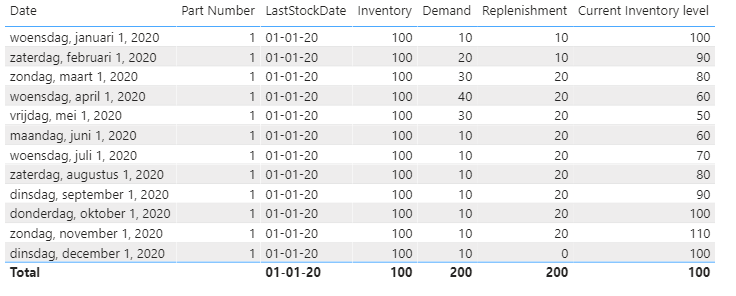

With this result.

This is based on your illustration of having only one initial stock position.

Here’s my sample file. I hope this is helpful.

eDNA - MPT Tool Test_Share.pbix (711.3 KB)